MIAMI, Okla. — With a symbolic turn of the shovel on Wednesday, officials with J-M Farms in Miami broke ground on a building project that will help the 40-year-old company continue to improve processes into the next decade and beyond.

The project, a tunnel facility, is being built north of the current J-M Farms building. It will house pasteurization and final compost conditioning operations. The project is expected to cost $9 million.

Scott Engelbrecht, vice president of operations, said the new 40,000-square-foot facility will house six tunnels that are 44 meters long and 14 meters wide.

Each tunnel will allow compost created outside to be finished in a controlled environment using air. The compost will be pasteurized to ensure no diseases are passed on during the growing process.

Engelbrecht said the company chose to go forward with this process after trips to Europe and Canada over the past three years.

Company officials are drawing upon equipment and designs developed by their Dutch counterparts for the new facility. Engelbrecht said the Dutch have spent much of the last two decades working to be more energy efficient.

“It’s going to be a more efficient and controlled process,” Engelbrecht said. “We hope this will allow us to have a more efficient yield increase, even without increasing our operation, by giving us more control in the process.”

The prior process used steam to heat the compost. The new process uses air.

Crossland Construction is overseeing the project. Engelbrecht said Crossland officials have worked with J-M Farms since the first construction project in 1979.

Producing mushrooms

Engelbrecht said officials hope the new composting process will help increase the company’s yield without needing to expand its growing operation. In the U.S., he estimates consumer demand for mushrooms increases about 4% percent each year.

He credits efforts by the Mushroom Council to promote mushrooms as a superfood, as well as demand for mushrooms as an additive to help lower the fat in meat, for much of the increase.

“People are learning how to use mushrooms at home,” Engelbrecht said. “It’s not just a luxury item to have in a restaurant. They are becoming an everyday staple.”

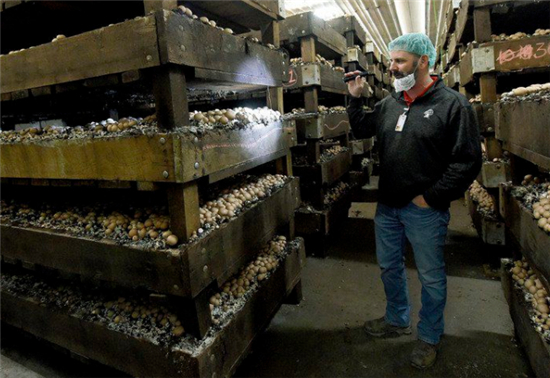

The company’s 500 employees process up to 70,000 pounds of mushrooms per day, 364 days per year. Two types of mushrooms are grown in the indoor beds: white button and browns. Within the brown type are portobello and cremini mushrooms.

All mushrooms are grown within the immediate area, either at the company’s main location on South 580 Road, outside of Miami, or at one of six satellite farms. The compost used is made from wheat straw, poultry manure and cottonseed meal — all of which comes from agricultural byproducts — and gypsum from mining operations in Oklahoma.

A pound of mushrooms typically contains 10 to 20 mushrooms. Employees process up to 26 million pounds each year.

A room with 250 beds will produce up to 35,000 pounds of brown mushrooms in 24 days; during the same time period, the room will produce between 40,000 to 45,000 pounds of white mushrooms.

once the mushrooms are harvested from the beds, employees remove the stems, along with any mushrooms that have fallen on the floor, and place them in bins. The bins are then taken by truck to the Quapaw Tribe’s nearby cattle operation to be used as a feed supplement.

Other byproducts from the mushrooms are used within local gardens or farms as compost. Additionally, the products have been used by the Environmental Protection Agency during the cleanup in Picher to help make new topsoil.

Engelbrecht said some mushroom byproducts are also being used in a University of Oklahoma project in Commerce helping to clean up waters entering Tar Creek.

“We [owners and employees] all live here. This is not an absentee ownership,” Engelbrecht said. “We are invested in this community literally and figuratively.”

Engelbrecht sees the new facility as the first step for company officials to continue to meet customer demands. It will also allow the company to continue to improve efficiency while cutting waste.

“We will be one of the leaders in the industry when it comes to adapting to this technology and the Dutch style of technology,” Engelbrecht said. “We will continue to grow, continue to increase and provide for the community.”

about J-M Farms

J-M Farms Inc., began in 1979 when Virgil Jurgensmeyer, Joe Jurgensmeyer and Darrell McLain founded the company in Miami. The company began as J&M Farms, but was later changed to J-M Farms when the Jurgensmeyers purchased McLain’s interest in April 1982.

Virgil Jurgensmeyer’s three sons, Curtis, Pat and Terry, continue to own and operate the business along with Engelbrecht. The annual payroll is approximately $15 million.

Company officials picked the first mushrooms for sale on March 13, 1980, and made their first delivery the next day to Associated Wholesale Grocers, of Springfield.

Company officials continue to strive to have the mushrooms processed from harvest to plate — either in stores or restaurants — within 36 hours under the J-M Fresh label. Mushrooms are delivered to locations in Oklahoma, Texas, Arkansas, Missouri, Kansas, Mississippi, New Mexico and Iowa.